ATG’s TÜV Rheinland and Exida certified functional safety specialists have worked with major clients in the Oil and Gas, Chemicals, Petro Chemicals, and manufacturing industries to assist with identifying their major risk exposures and setting up systems for ongoing risk management. Through this industry-specific knowledge and experience, we ensure that the risk management processes developed are specifically tailored to our client’s needs. Following are some of the services that we provide under Functional Safety Consulting:

What Our Client’s Says…

Baker Hughes Singapore has worked with ATG Asia Pacific for functional safety support. They are a truly professional and dynamic team, always willing to go the extra mile to get the job completed on time and at a fair cost.

Hazard Area Classification

HAZOP Facilitation

LOPA

Developing Functional Safety Management Plans (FSMP)

SIL assessment studies and SIL Selection

Safety Instrumented Systems (SIS) are used in many systems for the prevention and mitigation of safety-related hazards. An SIS may be made up of one or more Safety-Instrumented Function (SIF). The target Safety Integrity Level (SIL) of each safety-instrumented function (SIF) dictates the required performance of each SIF. That performance criterion is determined via a SIL assessment.

A SIL assessment may be performed for:

- Existing systems; or

- The design and implementation of new systems

The benefits of a SIL assessment include :

- Optimization of SIS safety performance

- Improvement in SIS reliability

- Reduced downtime due to spurious trips

- Compliance with the requirements of IEC 61508 and 61511

- Development of a best practice approach to process safety management.

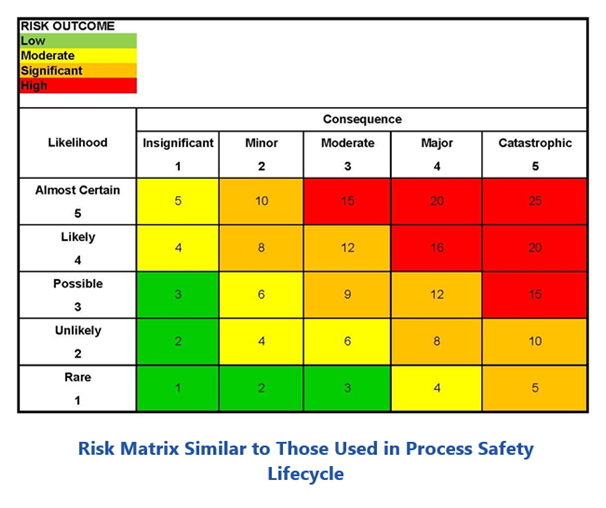

The SIL determination for a particular SIF is based on the expected likelihood and consequence of the hazardous event that the SIF is protecting against and the applicable risk criteria.

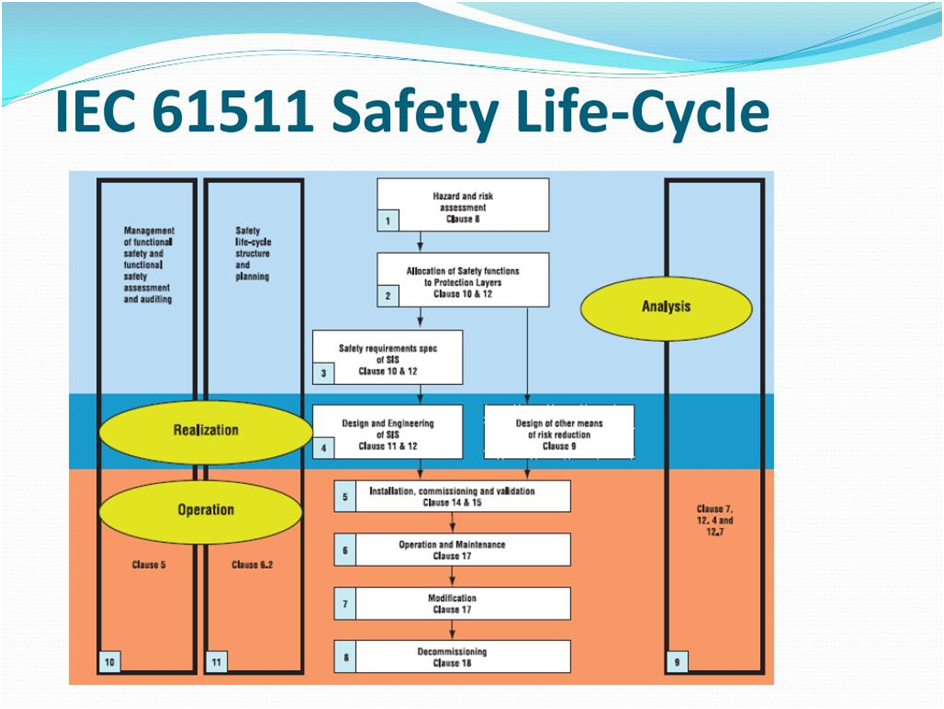

AS/IEC 61511-3 describes different methods for the SIL determination. The method of SIL determination for a specific case would be selected considering what best suits the needs and specifications of that system and the organization. Industry-recognized quantitative analytical techniques are used to assess the safety performance of the SIS. This ensures that the target SIL requirements are met and therefore, the intended risk reduction is achieved.

ATG’s SIL practitioners are qualified risk analysts who are also TÜV-certified Functional Safety Engineers. TÜV-certified Functional Safety Engineers have demonstrated their knowledge of SIS functional safety and satisfy the competency requirements of:

- AS/IEC 61508-1 Para 6.2.1

- AS/IEC 61511-1 Para 5.2.2.2

With specific skills in the application of functional safety combined with extensive knowledge of risk and safety management, ATG is well-placed to support any organization with its SIS safety management requirements.

Functional Safety Assessment

This should be carried out when the hazard and risk assessment is complete, and SIL target has been selected. Technically, it is possible to wait until the safety requirements are completed before starting functional safety assessment stage one, but only if this is available immediately following the SIL target allocation or SIL determination stage.

DO NOT WAIT FOR REQUIREMENTS TO FULLY STABILIZE BEFORE STARTING FUNCTIONAL SAFETY ASSESSMENT.

This is best completed alongside Factory Acceptance Testing, although it is advisable to start the stage two functional safety assessment activity when the instrumentation and logic solver selection has been made. Logic solver software review should commence when the software detailed design specification is available.

This must be complete before the safety instrumented system enters into service. To achieve this in practice, it is crucial that FSA 1 and FSA 2 stage actions are closed out.

Key documents for this stage include the installation, commissioning, and validation planning, and witnessed records that validation testing of each SIS and SIF is complete.

Since IEC 61511 edition 2 was published, it has been a requirement to conduct functional safety assessment of existing safety instrumented systems after some time in operation and maintenance.

This activity must be led by someone independent of the operations and maintenance team.

This is an assessment of any modification of a safety instrumented system (SIS) or safety instrumented function (SIF) hardware or software.

Except for fully like-for-like hardware changes, an FSA 5 may repeat elements of FSA 1, 2 and 3 for a limited part of the system.

ALL changes to software MUST undergo FSA 5.

Contact Us

Want to get in touch? We would love to hear from you. Here’s how you can reach us…